Veloci Prima Quick Connects – American Precision You Can Trust

When performance matters most, Veloci’s Prima quick connects deliver unmatched quality, durability, and ease of use in every detail.

To start, each fitting is proudly 100% made in Minnesota using solid 303 stainless-steel bar stock from Pittsburgh—the City of Steel.

From raw material to final polish, Veloci controls the entire process, ensuring consistent results and long-term reliability with every single unit.

As a result, you get exceptional durability, smoother operation, and tighter connections that outperform typical imports on any commercial pressure washing setup.

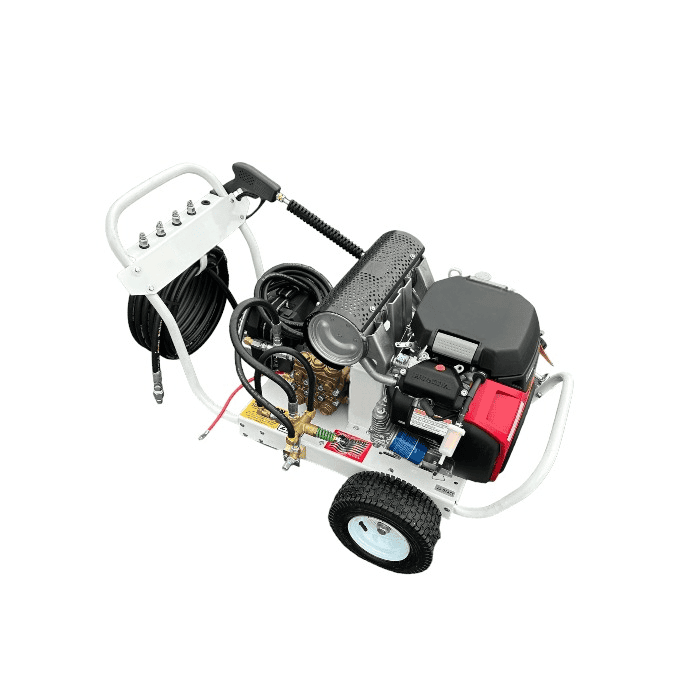

Where Prima Quick Connects Work Best

Prima fittings are designed for efficiency and reliability where time-saving matters most and connections must remain tight under pressure.

Use them confidently on:

-

Spray guns

-

Foam cannons

-

Wand extensions

-

Nozzle tips

-

Inline hose joints

Typically, Veloci’s 3/8″ fittings are placed between the pressure washer pump and spray gun—where high-flow 3/8″ hoses are used.

Meanwhile, 1/4″ quick connects are ideal at wand ends or spray gun outlets for rapid tool changes and better workflow on the job.

Engineered for Superior Precision and Performance

Unlike ordinary connectors, Prima fittings are machined to tight tolerances: ±127µm and ±1º on all working angular surfaces.

Therefore, every connection aligns perfectly—eliminating slop, reducing wear, and preserving seal integrity through repeated use and pressure cycles.

Additionally, each fitting undergoes digital inspection using a comparator, ensuring consistent quality from one batch to the next.

Veloci also de-burrs, polishes, and washes every unit to deliver smooth action, effortless engagement, and the cleanest finish in the industry.

Furthermore, EPDM seals resist high temperatures and strong chemicals, making these fittings ideal for tough conditions and frequent tool swaps.

And because Veloci machines every piece in-house, we ensure every fitting meets the highest standards for performance and longevity.

Know Your Threads – Quick Identification Guide

To avoid leaks and ensure proper fit, it’s critical to match your threads correctly before installation:

-

Male fittings = outer/exposed threads

-

Female fittings = inner/receiving threads

-

NPT (National Pipe Thread) = tapered, pressure-sealing thread used throughout North America

Because NPT threads seal by interference, accurate alignment and proper sealing technique are crucial to maintain pressure integrity.

Install Like a Pro – Seal Every Thread Correctly

Before tightening your fittings, always use the proper sealant to prevent leaks and ensure a strong, reliable hold under pressure.

When connecting NPT to NPT, apply 4–5 wraps of Teflon tape clockwise or 2–3 drops of Loctite thread sealant.

For NPT to BSP (common on European tools), apply 6–7 wraps of Teflon tape or extra Loctite for maximum sealing effectiveness.

Since BSP threads are straight, they engage sooner and tighten faster—yet still seal tightly when properly prepared.

So, take a few extra seconds during install, and you’ll enjoy leak-free performance in every application.

Reviews

There are no reviews yet.